About the Chemical Engineering Plant Capital Cost Estimator

This program allows easy calculation of the total fixed capital cost of a chemical plant using the detailed factorial method outlined by Towler & Sinnott1. Select from a list of over 50 equipment options, or specify custom equipment in a range of materials. Adjustment for inflation (CEPCI) and currency conversion is provided. Final ISBL and Total Fixed Capital Cost of the plant is calculated. Export a full pdf report of the results directly within the browser.

User Manual

The recommended procedure for a factorial method estimate as given by Towler & Sinnott1 is as follows:

- Prepare material and energy balances; draw up preliminary flow-sheets; size major equipment

items and select materials of construction. - Estimate the purchased cost of the major equipment items.

- Calculate the ISBL installed capital cost, using the appropriate factors and correcting for

materials of construction with the materials factors. - Calculate the OSBL, engineering and contingency costs.

- The sum of ISBL, OSBL, engineering and contingency costs is the fixed capital investment.

Step 1: Project Setup

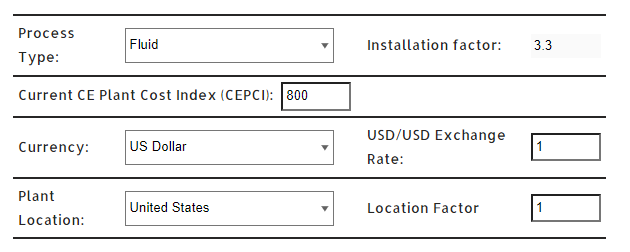

Specify the project setup data. The process type will determine the installation factors (note the purchase cost is calculated on the basis of selected material, and the equation by Towler & Sinnott is used for installed cost estimation). The Chemical Engineering Plant Cost Index (CEPCI) is an index published regularly by Chemical Engineering Magazine. Currency conversion can be accounted for, an up-to-date exchange rate must be input manually. A location factor may also be added (1 = US Gulf Coast basis).

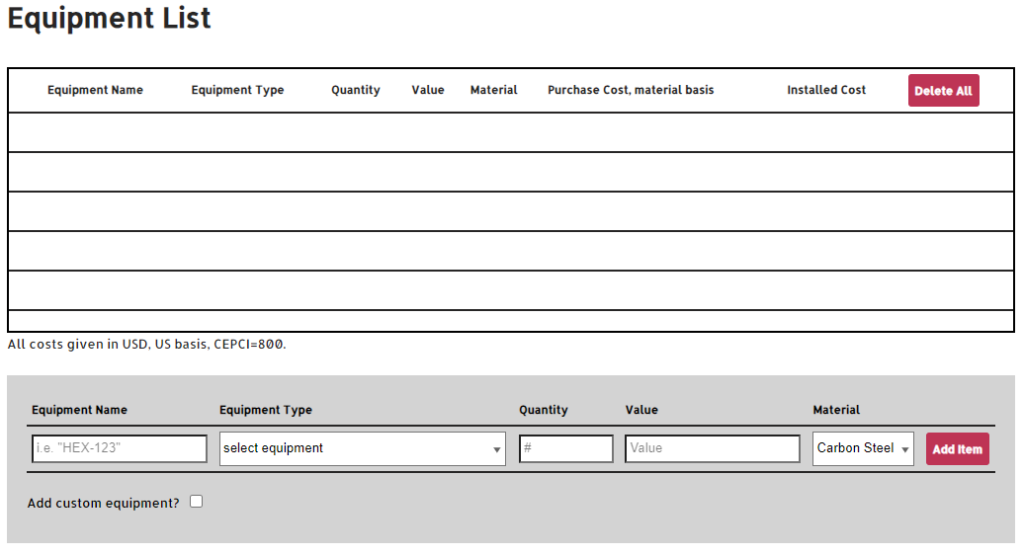

Step 2: Equipment List

Select the desired eqipment in the selection box. The minimum required inputs are the equipment type and the characteristic value. Please keep in mind the characteristic value is a different unit for each equipment type, if the data is not available from the process specifications it must be calculated. Additionally an equipment name, a quantity (default 1) and the material may be chosen.

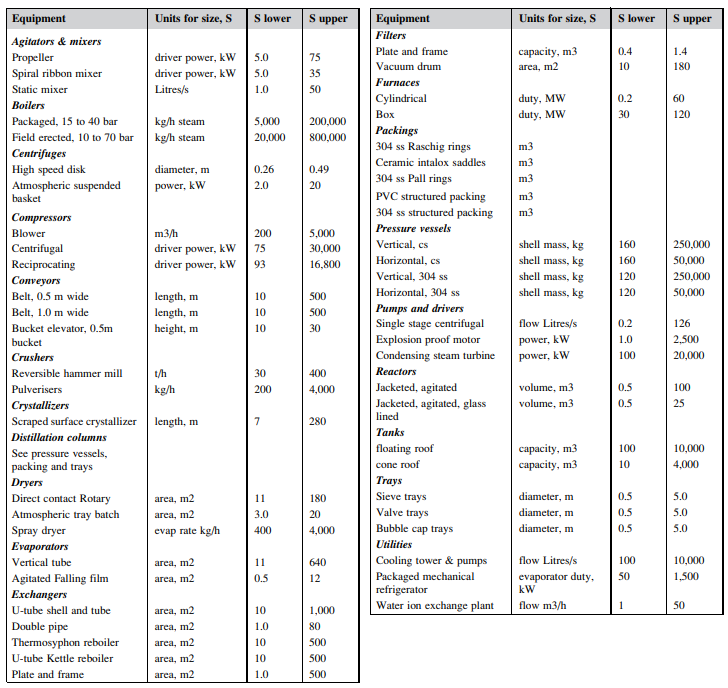

A list of equipment with their characteristic value (S) units and their limits for each equipment is given in Table 1 below.

Purchase cost (adjusted for selected material) and installed cost will be calculated and displatyed in the table. All costs are additionally adjusted for currency conversion (if specified), CEPCI inflation, and location factor (if specified).

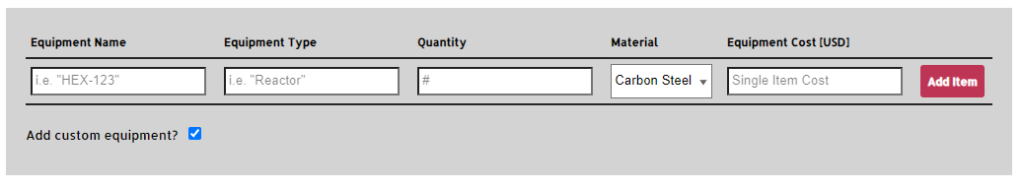

If a custom or specialised piece of equipment needs to be added, the “Add custom equipment” box should be checked. This allows cost data to be specified manually. The minimum required input is the installed equipment cost (for single item). The cost value is multiplied by the quantity (if specified, else a single item is assumed).

If you wish to delete a single item or all items (complete reset) press the corresponding delete button. Please be aware that there is no save feature at the current time, therefore it is likely progress will be lost if the page is re-loaded.

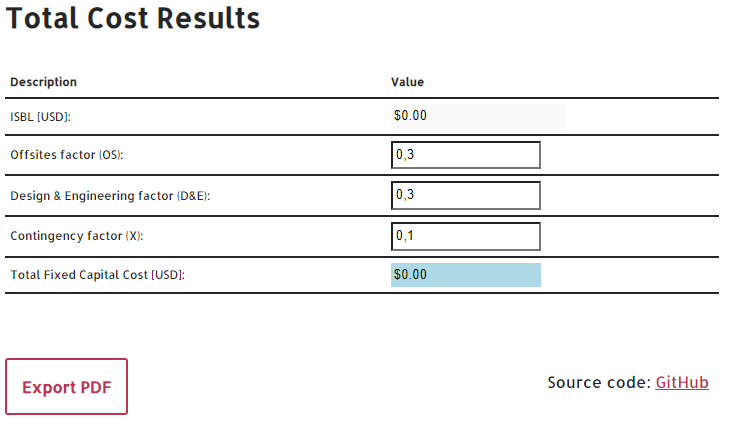

Step 3: Total Fixed Capital Cost Estimation

The final section displays the total installed cost inside battery limits (ISBL). Custom factors may be specified for Offsites (OS), Design & Engineering (D&E), and Contingency (X), however typical values are given by default. The final Fixed Capital Cost is calculated. The results including the project setup equipment table can be exported as a PDF.

References

- Towler, G. and Sinnott, R.K. (2020). Chemical Engineering Design (Sixth Edition). Butterworth-Heinemann.

- The University of Manchester. Chemical Engineering Plant Cost Index. [online] Available at: https://personalpages.manchester.ac.uk/staff/tom.rodgers/Interactive_graphs/CEPCI.html?reactors/CEPCI/index.html.